The ‘Triple-Oh’ or the one that got it all started

In 1997 1998 1999 2000 and 2001 I performed almost constantly with my flamenco group and I used to play a song called ‘Dos Amigos’ that featured an electric guitar solo.

So I would take one of my original made-specially-for-me Tony Zemaitis guitars to the shows to play that one solo. Pretty soon it became clear that THAT was not the way to do it: these guitars

for which I had paid around $7-8000 each were now worth many times that (Tony had passed away) so I went shopping. And also the Japanese ‘Zemaitis company’ had started to build guitars which were at the time $10,000 and I could not bring myself to buying one of those. I’d just built an all-tube overdrive pedal and a VOX-inspired tube amplifier and got cocky: “”I’ll just build one myself.”

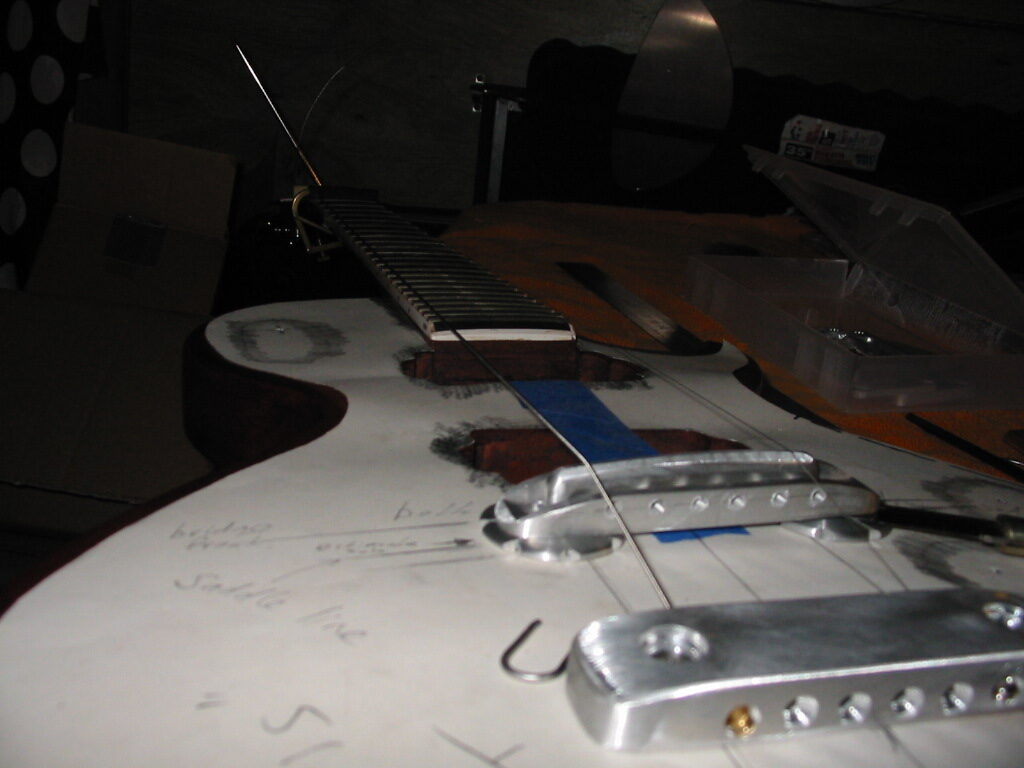

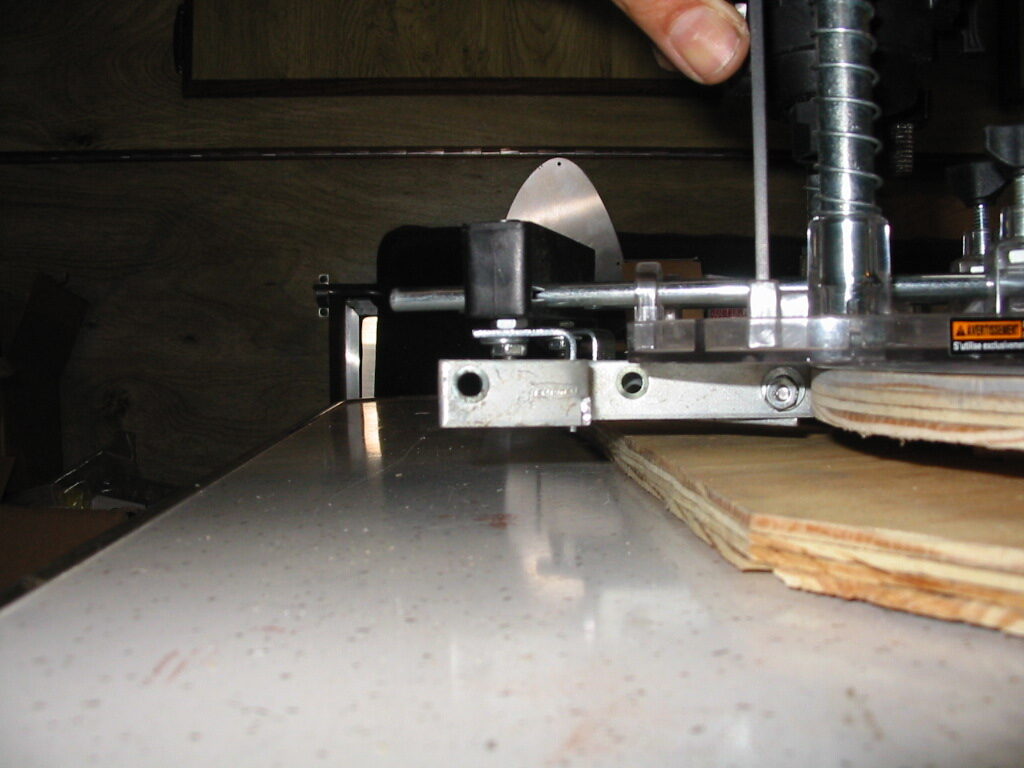

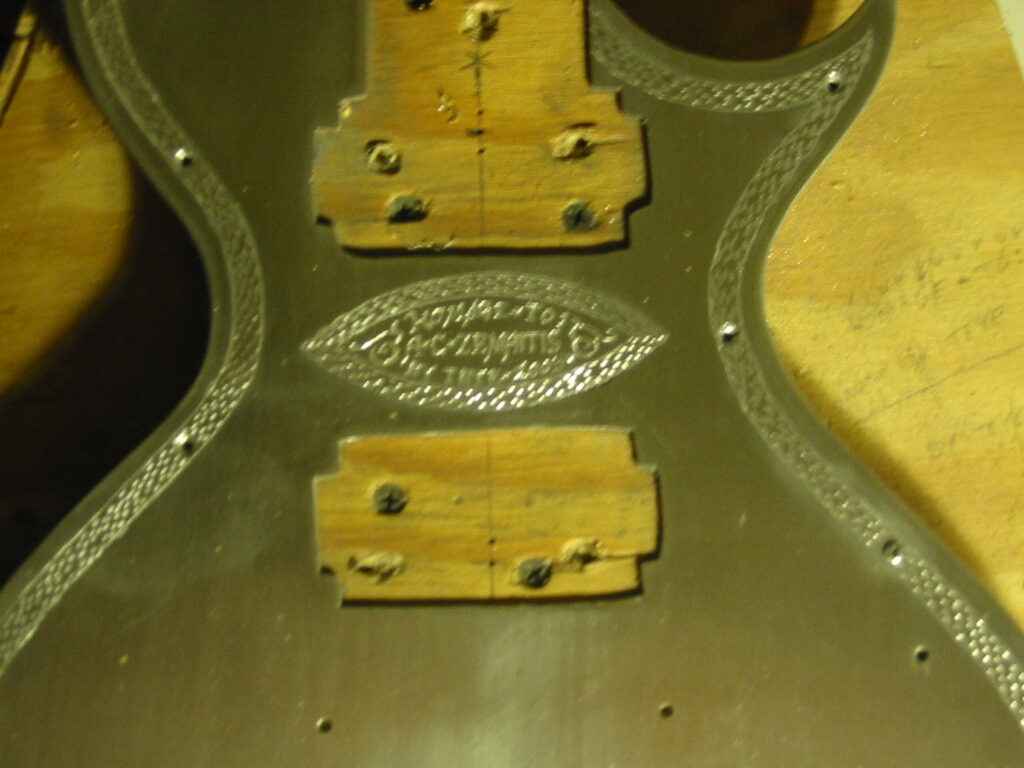

And that is how that first guitar came about. I basically built a kind of copy of my best sounding Zemaitis, of course I could not resist the temptation to make some ‘improvements’ that upped the resonance, but this 2005 guitar pretty much started it all: I showed her to some people at the Dallas Guitar Show of 2006 and everybody was floored. Some people offered me thick wads of cash, and Paul Reed Smith said: “YOU made this? You will be making many more guitars my friend!!!”

Well Paul, you were spot on my friend! And THANK YOU for the encouragement.

And this ‘000’ sounded so glorious that I immediately went to work building another guitar, this time the whole design featuring my own ideas and wishes, and that guitar became the number ‘001’ A-series ‘La India’.

Nevertheless here she is: number (as we called her later) Triple-Oh or 000.

And thus this became the instrument that made me a guitar builder…

Because just now, my wife and I had decided to stop touring and performing for a living and start a family, so we were both looking for a plan-B: and mine was to become a guitar-maker.

Here my very FIRST build, next to the ‘000’, at a show.

Time to get LOUD! Here you see my very first build (a copy of my Dan Armstrong that I made together with my father in 1981) and then the 2005/2006 ‘000’.